|

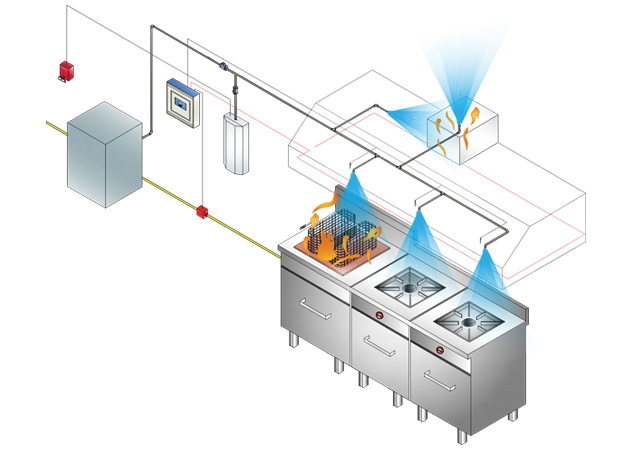

The Kitchen Fire Suppression System is designed to provide fire protection in hoods and ducts of cooking appliances for restaurants. |

|

The basic system consists of wet agent tank enclosed in a cylinder mounting box, Temperature Sensors, Heat sensing cable, Control panel, Nozzles, piping, & water storage tank (optional) etc. |

|

The system provides automatic actuation with an option of being actuated manually through a remote manual pull station. |

|

The system is also capable of shutting down other appliances on system actuation, if required. |

|

Additional equipments such as remote manual pull station, mechanical and electrical gas valves, pressure switches, electrical switches & accessories such as alarms, warning lights, etc. can be integrated with the system. |

|

As the fire is detected Control Panel activates the wet agent tank and wet agent is discharged extinguishing the fire. |

|

Single and Multi Wet Agent tank system is available. |

| |

|

| |

| Kitchen Fire Suppression System- Activated |

|

|

| |

| System Operation : |

|

|

The SKFS System suppresses fire by spraying the SYNERGY Low pH Liquid Fire Suppressant on the plenum area, the filters, cooking surfaces, and the exhaust duct system with a predetermined flow rate. |

|

When the liquid agent is discharged onto a cooking appliance fire, it cools the grease surface, and reacts with the hot grease (saponification) forming a layer of soap-like foam on the surface of the fat. |

|

This layer acts as insulation between the hot grease and the atmosphere, thus helping to prevent the escape of combustible vapors. |

|

The system is designed as a hybrid (agent and water) system. |

|

Upon actuation, agent is discharged onto the hazard area. Immediately following discharge, the waterline system is activated and it allows water to flow onto the same hazard areas, continually refurbishing the foam blanket and cooling the hot appliance to prevent reignition. |

|

| |

| Control Panel |

|

|

Digital Temperature display |

|

Battery Back-up |

|

System Low Pressure Indicator |

|

Emergency Activation Switch |

|

Automatically Shuts off the Gas Supply Valve on activation |

|

Turn off other devices as required. |

|

Battery Charging Indicator |

|

Fault Indicator |

|

Pre Audio Visual alarm before Activation |

|

|

|

|

| |

| Agent Properties : |

|

|

Appearance : Light Blue |

|

Freeze Point : -24 oC |

|

Boiling Point : 230 oC |

|

Specific Gravity : 1.2 – 1.5 g/cm3 |

|

pH : 8.5 – 11 |

|

| |

| Suitable For Following Kitchen Appliances : |

|

|

Fryer - Single Nozzle Protection |

|

Multiple Nozzle Fryer Protection |

|

Tilt Skillet/Braising Pan |

|

Range Protection |

|

Griddle Protection |

|

Chain Broiler Protection |

|

Overhead Chain Broiler Protection |

|

Upright/Salamander Broiler Protection |

|

Gas-Radiant/Electric Char-Broiler protection |

|

Lava-Rock (Ceramic) Char-Broiler protection |

|

Natural Charcoal Broiler Protection |

|

Alternate Ceramic/Natural Charcoal Char-Broiler Protection |

|

Wood Fueled Char-Broiler Protection |

|

Wok Protection |